Fifty hours a week is not a lot of time for doing both leader's standard work and continuous improvement work. It's disrespectful to waste part of someone else's 50 hours.

Research and publish the best content.

Get Started for FREE

Sign up with Facebook Sign up with X

I don't have a Facebook or a X account

Already have an account: Login

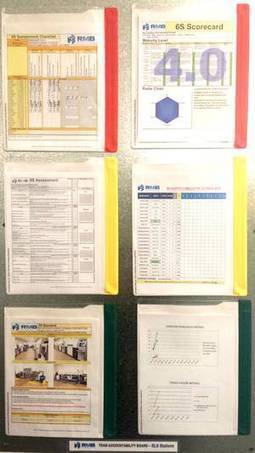

Kaizen or Continuous Improvement is a Rapid Improvement Event using Lean Six Sigma in a 3-5 day event

Curated by

Steven Bonacorsi

Your new post is loading... Your new post is loading...

Your new post is loading... Your new post is loading...

Ashok Ramachandran's curator insight,

March 8, 2013 7:01 PM

Everyone wants to improve things. But, here is a scientific approach that will allow you to figure out what works and make that a part of your new way of doing business. |

|